Industrial QC requires high accuracy + high robustness, and YOLOv12's customization capabilities can meet the demand:

1. Data preparation phase::

- Use LabelImg to label defective samples, noting the diversity of light conditions

- Data enhancement focuses on the use of ColorJitter and MotionBlur.

- Dividing the training/validation/testing set by 8:1:1

2. Migration learning configuration::

- Load pre-training weights: model = YOLO('yolov12m.pt')

- Freeze the first 20 layers of the backbone network: freeze=[0,19]

- Set initial lr = 0.001 and decay by cosine

3. Key training techniques::

- Enable -rect rectangle training to reduce padding

- Add Focal Loss to address sample imbalance

- Preventing overfitting by stopping early (PATIENCE=50)

4. Deployment options::

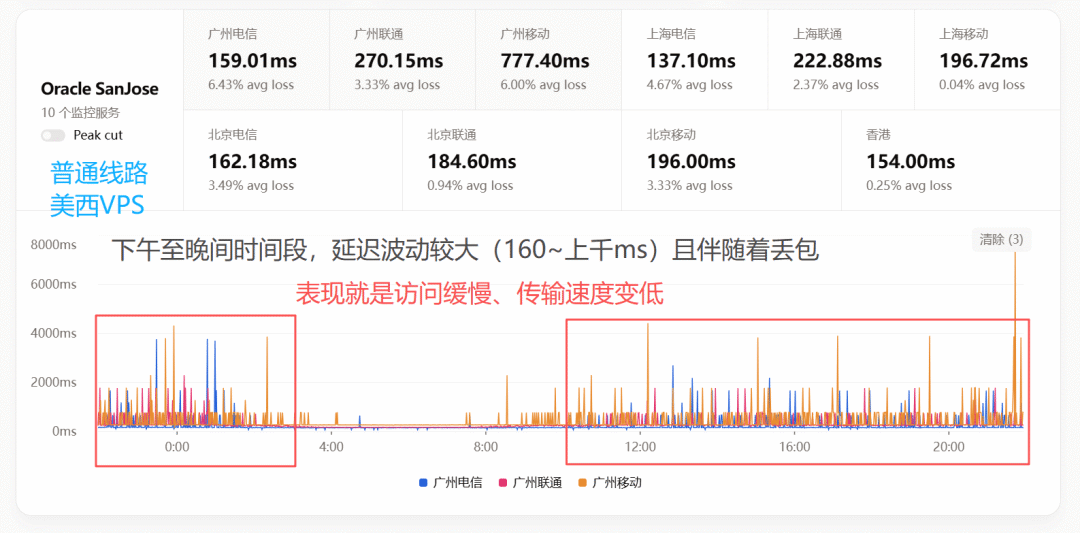

- Deployment to production line industrial controllers with ONNX-TensorRT

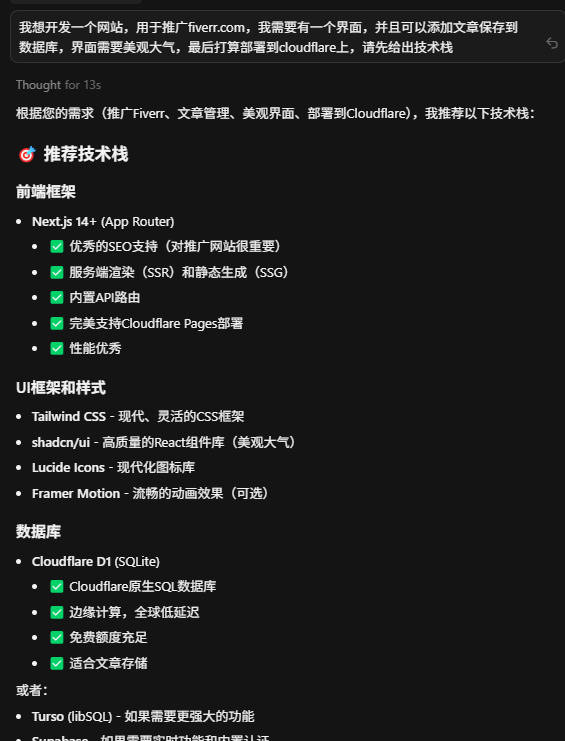

- Developing Django/Flask Visualization Interface

- Integrated PLC communication module triggers sorting actions

Typical implementations show that 3,000张样本训练后mAP@0.5可达92.3% takes ≤15ms to detect a single piece.

This answer comes from the articleYOLOv12: Open source tool for real-time image and video target detectionThe